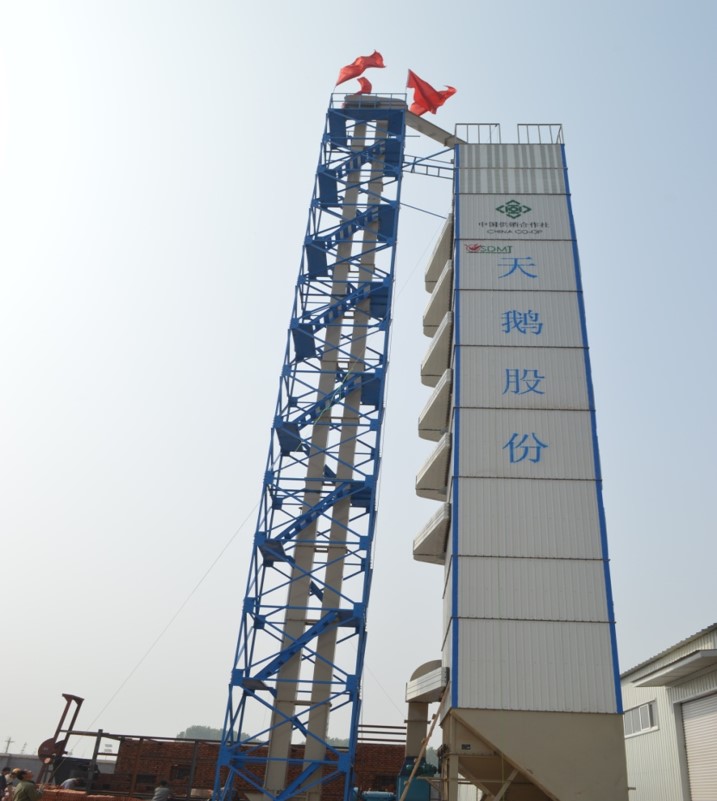

Dryer Tower

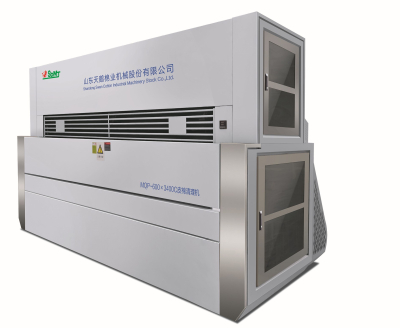

1. The application of counter-current drying, tempering and cooling technology makes the baked grain more close to the effect of natural drying.

2. Adopt high, medium and low temperature adjustment drying technology to ensure drying quality and reduce energy consumption.

3. Adopt uniform distribution technology of ventilation section, it can makes the whole grain layer evenly heated and dehydrated to ensure the uniform moisture of the grain after drying.

4. Double shell integrated design, waste heat recovery, reduce energy consumption, beautiful appearance and environmental protection.

The whole process of drying storage mechanization, online detection, intelligent control, automatic adjustment of drying temperature, video monitoring, fault alarm, one-click start and stop.

Product Introduction

The intelligent grain drying system is suitable for the grain drying process.It adopts advanced technology and the control system, effectively deal with a lot of food, to ensure food quality and safety in the drying process.

The intelligent grain drying system is composed of drying tower, heating system, circulation fan, control system and so on. During the drying process, the grain is fed into a drying tower and the air is then heated by a heating system to produce hot air.Hot air was blown evenly to the grain pile by a circulating fan to evaporate the water on the surface and inside the grain.At the same time, the control system will be within the drying tower on parameters such as temperature, humidity, wind speed monitoring and regulation, to ensure that the drying process control and accuracy.

Intelligent grain drying systems are widely used in grain storage and processing industries. Can be used to dry a variety of food, such as grain, beans, oil and so on.By using smart food drying towers, farmers and food processing enterprises can better manage and protect food resources, improve food quality, and reduce losses, thereby providing safer, high-quality food to the market.

Features

1. Drying capacity: Grain tower dryers have a specified drying capacity, measured in bushels per hour, which indicates the amount of grain that can be dried in a given time frame.The capacity of the dryer can change depending on the type and size.

2. The temperature and air flow control: grain tower dryer often provides adjustable temperature and airflow control.These controls allow operators by adjusting the temperature and air flow to optimize the drying process, in order to achieve required less moisture in grain.

3. Safety features: Safety is an important aspect of cereal tower dryer.They are equipped with all kinds of security features, such as emergency shutdown switch, pressure reducing valve, flame sensor and fire extinguishing system.These features help minimize the risk of accidents, equipment damage, and fire.

4. Grain monitoring system: modern grain tower dryer tend to have the advanced monitoring system.These systems in the whole drying process to provide real-time data of temperature, humidity and airflow.They can also be programmed to automatically adjust the Settings in order to get the best dry effect.

Technical Specification

Model Parameter | Capacity(t/d) | |||

Precipitation 5% | Precipitation 10% | Precipitation 15% | Precipitation 20% | |

SHSN-100 | 300 | 150 | 100 | 75 |

SHSN-150 | 450 | 225 | 150 | 112 |

SHSN-200 | 600 | 300 | 200 | 150 |

SHSN-300 | 900 | 450 | 300 | 225 |

SHSN-500 | 1500 | 750 | 500 | 375 |

SHSN-600 | 1800 | 900 | 600 | 450 |

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1) . Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on. This can be done by visual inspection or using auxiliary tools (e.g. microscopes, measuring instruments).

(2). Functional test: Check whether the function of the product is working properly. This can be done by operating the product, performing functional tests, or using specific test equipment to verify the performance and functionality of the product.

(3). Packaging inspection: check whether the packaging of the product is intact, whether the label is clear, and whether the packaging materials meet the requirements. This ensures that the product is not damaged during transportation and storage, and that it can be properly identified and identified.

(4). Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

Packing and Delivery

1. Disconnect and disassemble: First disconnect the grain tower dryer from any power or utility. Break the dryer down into smaller, manageable parts whenever possible. This facilitates packaging and transportation and reduces the risk of damage during transportation.

2. Clean dryer: Before shipping, the packaging staff will thoroughly clean the grain tower dryer, which will help prevent contamination and ensure safe transportation.

3. Fix loose parts: If there are loose parts or parts that cannot be removed, the packaging personnel will firmly fix them to the main body of the dryer. Use straps, ropes or other appropriate fastening materials to prevent them from moving and being damaged during transportation.

4. Protect vulnerable parts: packers will use appropriate fillings, such as bubble wrap or foam, to protect vulnerable parts of the grain tower dryer, such as control panels, electrical connections or vulnerable parts. This helps to cushion shocks and vibrations during transport.

5. Pack with care: Our packaging and shipping personnel will place the disassembled or filled parts of the grain tower dryer into the appropriate container, ensuring that the container is strong enough to withstand the weight of the dryer during transportation. Use padding or filler material to fill any gaps and minimize movement within the packaging.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.