Wheat Harvester

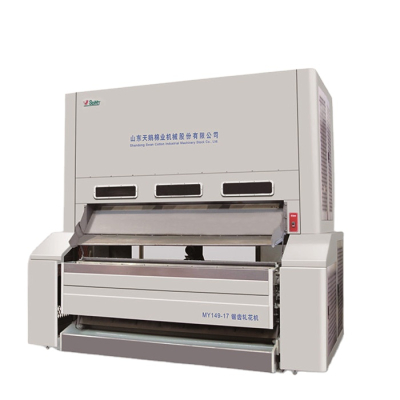

1. Cutting table optimized, using knife type picking: no damage to corn, higher efficiency, more durable, lodging corn can be harvested, complete straw crushing treatment at the same time.

2. Using the walking standard hydrostatic four-wheel drive device, transmission with 30 tons of electric shift gearbox, simple and convenient operation, faster walking speed, stronger ability of climbing and get out of the trouble.

3. Widen the wheel base, increase and highten tires, and reduce the center of gravity of the vehicle: walking is more stable and the operation is more suitable for a wider area.

4. Advanced single longitudinal axial flow threshing technology, low damage rate, good separation effect. Axial flow roller adopts electric regulation, stepless speed regulation, easy to operate.

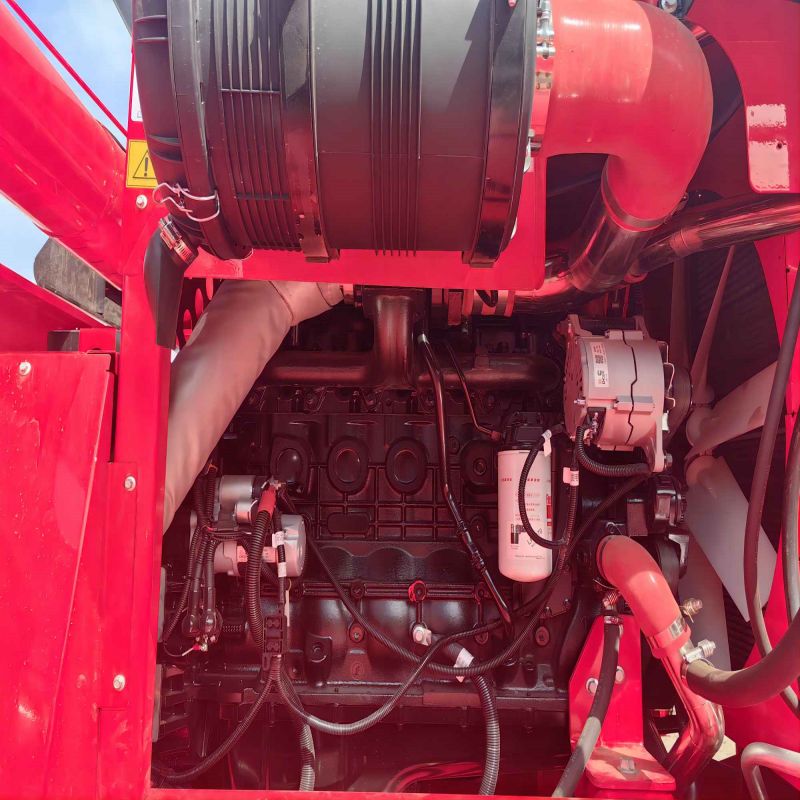

5. Powered by Cummins six-cylinder 300 HP engine: powerful, faster operation, adopt the best transmission ratio, saving average fuel consumption.

6. Standard with three kinds of threshing concave plate, two kinds of separation concave plate, two kinds of cleaning screen, can achieve a variety of crops harvest, truly realize a multi-purpose machine.

Products Introduction

Shandong Swan 4500 food combine harvester is a kind of harvester that can complete harvesting, threshing, separating straw, removing impurities and other processes, and harvest food directly from the field.High labor efficiency, low failure rate, suitable for large-scale grain planting areas.

A wheat harvester, also known as a combine harvester, is a type of agricultural machinery specialized in harvesting wheat crops. It is a versatile piece of equipment that combines a number of operations, including cutting wheat, separating grain from straw and collecting harvested wheat.

Product Details

(1). The cutting table has a variety of choices according to the planting method and the harvesting straw treatment requirements.

(2). Cummins 6 cylinder 300 HP engine: strong power, faster working speed, using the best transmission ratio, saving average fuel consumption.

(3). Vehicle Frame

The frame is made of high-end cotton picker material and adopts mortise welding process to ensure that the frame will not be deformed, opened or broken.

(4). Front Axle

Equipped with electronic shift transmission and integrated front drive axle, deadweight can reach 30 tons.

(5). Rear Axle

Four-wheel drive adopts "one pump three motors", each motor can operate independently, greatly improving the ability to get rid of failure.

(6). Luxury Cab

Standard air conditioning, the hanging seat, integrated operation platform, simple and comfortable.

Technical Specification

ltem | Unit | 4500 |

Harvesting rows | row | 12KG/S |

Application scope of row space | mm | |

Power of engine | KW(HP) | 221(300HP) |

Working efficiency | h㎡/h | Around 2 |

Volume of tank | m³ | 9 |

Height of unload | mm | 5100 |

Weight | kg | 15000 |

Overall size(L×W×H) | mm | 9500×6100×4300 |

Type of walk | hydraulic four-wheel drive |

Special Transportation Design

According to the previous delivery experience, there are certain differences in the structure and size of the grain harvester and the conventional equipment. Therefore, in cross-border transportation, we will use special packaging and packing schemes to ensure product safety and no damage.

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1) . Functional test: Check whether the function of the product is working properly. This can be done by operating the product for functional testing.

(2) . Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on.

(3). Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4). Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

Application

1.On-The-Go Processing: Some Wheat Harvesting Machines are equipped with features that allow for on-the-go processing. This means that the machine can thresh, separate, and clean the wheat grains while continuing to harvest, improving efficiency and saving time.

2.Straw Management: After the grain is harvested, the machine often processes the remaining straw to create neat windrows or spreads it back on the field as mulch. This helps with soil fertility, erosion control, and organic matter recycling.

3.Navigation and Control: Modern Wheat Harvesting Machines often incorporate advanced navigation systems, including GPS and sensors, to optimize operating efficiency and reduce overlap or missed areas.

4.Transport and Storage: Wheat Harvesting Machines can also be equipped with features for unloading the harvested grains into trucks or other storage containers, enabling efficient transportation and storage.

Company Information

Swan cotton industry in shandong machinery co., LTD. Is a SMC) of the listed companies in shandong province. Its predecessor was established in 1946.Set research and development, precision production, marketing services, capital operation as one, specializing in mechanized, intelligent, information cotton processing equipment to provide one-stop supply and service, products are exported to more than 30 countries.Its domestic market share has topped the list for several consecutive years.Marketing service network all over the world's major cotton production areas in China.

With cotton machinery as the main business, the company strives to promote the transformation and upgrading of the cotton industry, create a new era of smart factories, build the world's first brand of cotton machinery, actively expand to the intelligent agricultural machinery equipment industry, and comprehensively step into the high-end equipment manufacturing industry.

Shandong Tianyi Cotton Machine Co., Ltd. has four technology centers and production bases, Jinan, Shandong, Wujiqu, Xinjiang, Halaer, Inner Mongolia, Montgomery, USA, three national high-tech enterprises and six provincial innovation platforms, which have led the technological progress of the industry for many years.It is a high-tech enterprise of Shandong Province, a technical support unit of the "National Key Promotion Plan for Scientific and Technological Achievements", and a national key research and development plan undertaking unit of the "13th Five-Year Plan".