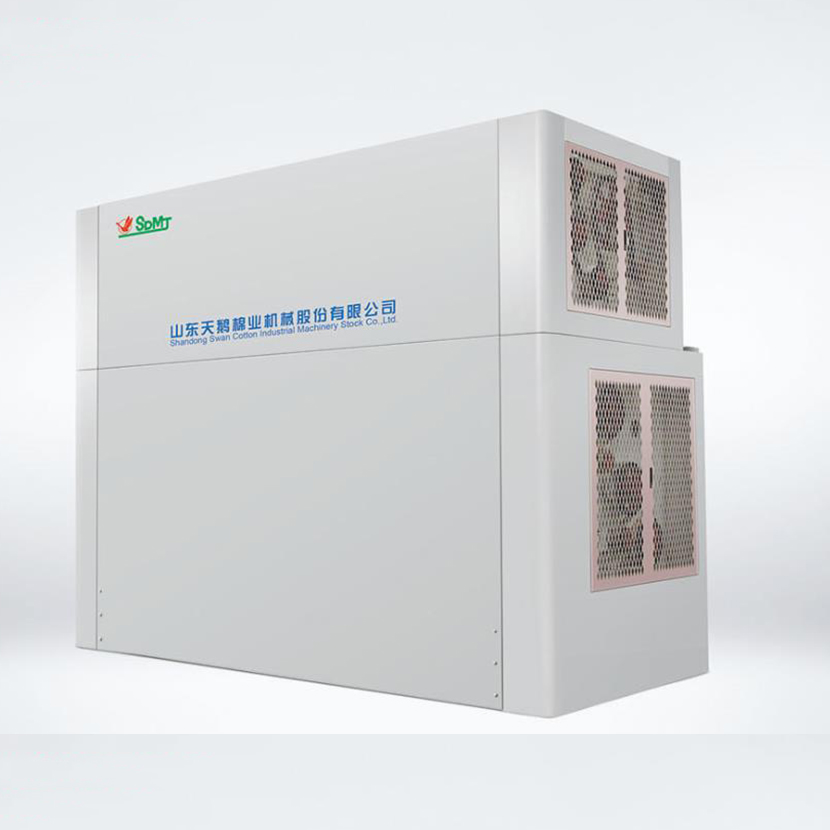

Cotton Pre-Cleaning Machine

1. To specially discharge boll shell and sticks in machine-picked cotton and manual fast-picked cotton.

2. Reasonable structure , strong manufacturability ,little damage to seed cotton.

3. Adopting many new techniques and new materials , stable and reliable performance.

4. Big trash discharge rate is not less than 8596 , low cotton loss.

5. Visible protection cover adopts uses advanced phosphating process and plastic powder coating technology, strong adhesion, corrosion resistance ,oxidation resistance and elegant appearance.

Product Introduction

Extract-type seed cotton cleaning machine is a kind of equipment used for seed cotton cleaning. It adopts advanced cleaning technology, which can effectively remove impurities in seed cotton and improve the quality and purity of seed cotton.It is mainly used for picking cotton by washing machine and picking cotton by hand.The cotton seed washing machine produced by Shandong Swan Cotton Machinery Co., Ltd. has the characteristics of high efficiency, reliability and long service life.

Technical Specification

Model | Capacity(kg/h) | Power(kW) | Overall Dimension (LxWxH)(mm) | Weight(kg) |

MQZT-15C | 13000~15000 | 30 | 4850x2350x3885 | 7000 |

MQZT-12C | 10000~15000 | 22 | 4400x2350x3885 | 6400 |

MQZT-10C | 8000~10000 | 18.5 | 3900x2350x3885 | 5200 |

Note | The above capacity means processing capacity of standard grade seed cotton whose moisture rate is not more than 7% and ginned lint reaches quality standard. | |||

Packing and Delivery

(1). Each machine is well supported and reinforced inside the container to ensure safe arrival at the destination port.

(2). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

1. Visual Inspection: Begin by visually inspecting the entire machine for any signs of damage, wear or corrosion. Take a close look at each component, including the blades, belts, gears and bearings, to make sure they are in good condition.

2. Functionality Test: Use a small amount of seed cotton to test the machine's functionality. Check to see if the machine runs smoothly and effectively separates cotton fibers from seeds and debris. Note any unusual noise or vibration during operation.

3. Safety Features: Evaluate the presence and function of safety devices such as emergency stop buttons, guards and warning signs. Ensure that these features are in place and working properly to ensure the safety of the operator.

Company Information

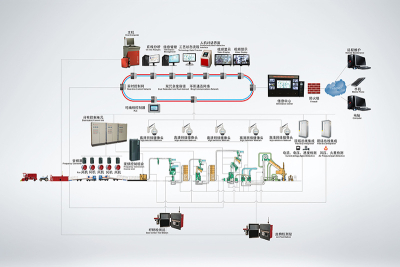

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.