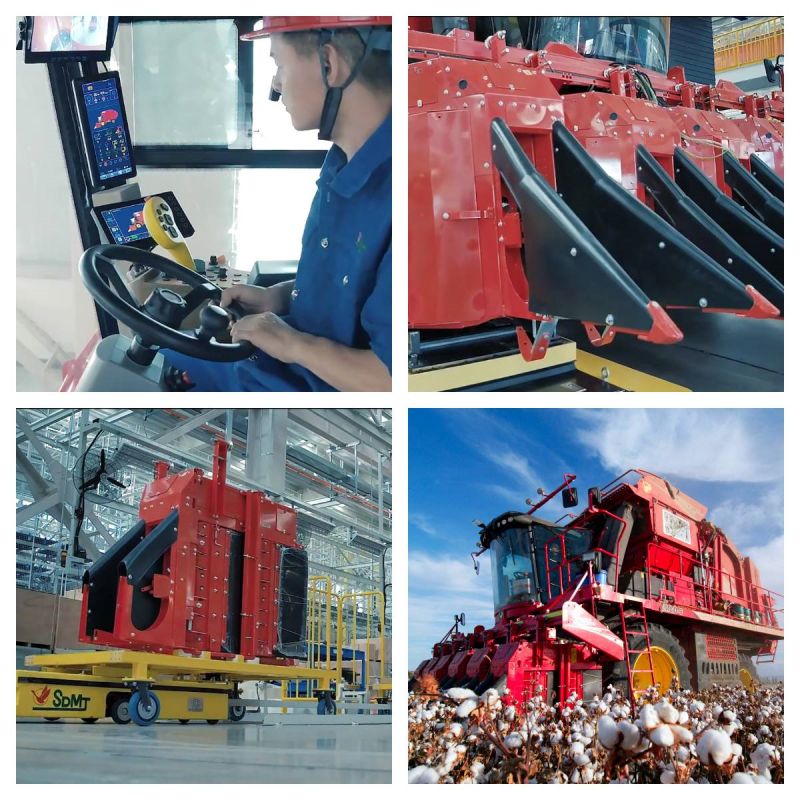

Mechanical Cotton Harvester

1. Equipped with a 325HP Cummins engine ,electronically controlled hydraulic transmission, optional four-wheel drive and a top picking speed of 7.1km/h.

2. The most advanced PR016 picking head is adopted to optimize the spindle picking track and drum speed. The picking rate is as high as 93%,with little damage to fiber and low impurity rate in picked cotton.

3. Adopt controllable continuous and uniform cotton discharge technology and forced feeding system, which effectively reduces the probability of blockage . The diameter of cotton module can be adjusted according to the field conditions.

4. Independently designed high-end cab, power shift gearbox, hydraulic clutch box, man-machine interface and user-friendly design to make operation more comfortable.

5. The whole machine adopts CAN bus intelligent control system, which can realize automatic monitoring, fault alarm, moisture detection and other functions.

6. The core electrical components of the whole machine are all imported, with stable and reliable performance;independent research and development of important parts and components, low cost of use and maintenance.

7. Independently designed and developed electronic control program, to upgrade the system according to the needs of product development .

8. The whole machine adopts the mature structure of six-row cotton packing picker which can realize automatic deformation, easy to transport and road driving, easy to maintain.

9. The sales and service outlets are all over the main cotton producing areas in Xinjiang, providing driver training, machine maintenance, after-sales service guarantees worry-free.

Products Description

4MZD-3 type three row cotton piccher is our company according to the market demand independent research and development of new products. It has been widely used in cotton harvesting in Xinjiang, the main cotton producing area in China.Because of its flexibility, low failure rate, stable performance and other characteristics, it has won the praise of users.

Product Details

(1). Car style design luxurious and comfortable cab, seat and control device can be adjusted according to the needs of the driver.Equipped with air conditioning, USB port and 12V power supply, it provides users with a better driving experience.

(2) Better service.Each cotton picking machine is equipped with 2-3 technical and maintenance personnel to ensure uninterrupted operation of the cotton picking machine and timely troubleshooting.Equipment application area has spare parts warehouse, to achieve all-weather spare parts supply, customers can enjoy the original spare parts bring comfort and excellence.

(3) Higher work efficiency.Using more powerful 770 horsepower cummins engine, equipped with the latest design of pickup head, top pick up speed of 7.1 km/h, work efficiency can be improved by more than 30%.

(4) Intelligent control.The real-time status and data of cotton picker can be mastered through the vehicle human-machine interface, which is convenient for users to make relevant plans and decisions quickly and timely.

Technical Specification

Project | Unit | Parameter | ||

The Machine Parameters

| ||||

Net Weight | T | 24 | ||

Driving Speed | Cotton Field | Grade I | km/h | 0-7.1 |

Grade II | 0-8.5 | |||

Highway | Grade I | 0-15 | ||

Grade II | 0-27 | |||

Engine Rating | kw | 424(325HP) | ||

Minimum Turning Radius | m | 6 | ||

Machine Size (Transport) L x Wx H

| mm | 11010x3300x3900 | ||

Machine Size (Picking) L x Wx H | mm | 9680x4200x4600 | ||

Wheelbase | mm | 4095 | ||

Drive Mode | mm | 4WD | ||

Parameters for Cotton Picking Head

| ||||

Number of Cotton Picking Head

| pcs | 3 | ||

Number of Seat Tube | pcs | Front 16,back 12

| ||

Number of Picking Spindle per Seat Tube | pcs | 20 | ||

Total Picking Spindles | pcs | 1680 | ||

Capacity Parameters | ||||

Cotton Module Weight | kg | 1400 | ||

Diesel Oil Tank | L | 600 | ||

Cleaning Fluid Tank | L | 700 | ||

Grease Box | L | 140 | ||

Special transportation design

According to the previous delivery experience, there are certain differences in the structure and size of the cotton picker and the conventional equipment. Therefore, in cross-border transportation, we will use special packaging and packing schemes to ensure product safety and no damage.

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1). Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on. This can be accomplished through visual scrutiny or by utilizing supplementary tools.

(2). Functional test: Check whether the function of the product is working properly. This can be done by operating the product for functional testing or by using specific test equipment to verify the performance and functionality of the product.

(3). Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

(4). Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

Application

1. Increased productivity: Cotton pickers are able to harvest cotton continuously, thus increasing the productivity of farmers. These machines are equipped with high-capacity collection bins that allow for a longer harvest time before unloading harvested cotton.

2. Precision and Accuracy: Modern cotton pickers are equipped with advanced technologies such as GPS and sensors to ensure precise and accurate harvesting. This technique helps optimize the harvesting process to avoid overlapping or missing any cotton plants.

3. Versatility: The picker is versatile and can adapt to different field conditions and cotton varieties. They can be adjusted to harvest different plant sizes and handle different ripeness.

4. After harvest efficiency: the machine is usually equipped with a built-in cleaner and separator, to clear away the debris in the harvest of cotton fiber, leaves and plant material.That improve the quality of the cotton harvest, make it more suitable for further processing.

Company Information

We are a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

The company is mainly concerned with cotton spinning machinery, focusing on promoting the transformation and upgrading of the cotton industry, creating a new era of intelligent factories, building the world's first brand of cotton spinning machinery, and actively expanding to the industry of intelligent agricultural machinery and equipment, and comprehensively entering into the high-end equipment manufacturing industry.

Shandong swan cotton machine co., LTD. Shandong jinan, the wu Qu in xinjiang, Inner Mongolia hailar, Montgomery four technology center and production base in the United States, three national high and new technology enterprise and six provincial innovation platform, leading the industry technology progress for years.Is a high and new technology enterprise of shandong province, "national key scientific and technological achievements project" technical support unit, "much starker choices-and graver consequences-in" national key research and development plan for unit.