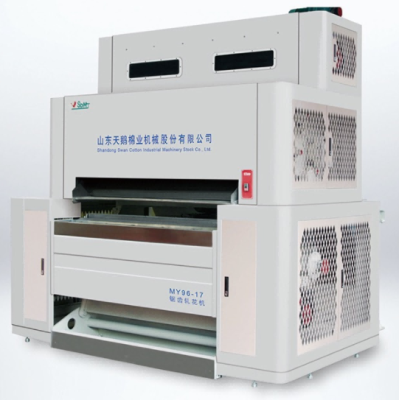

Automatic Cotton Ginning Machine

1. Designed for large scale and intensive cotton ginning factory,good at machine-picked processing,also hand-picked cotton processing.

2. Adopting extracting type feeding and removing foreign matter.

3. Adopting design of big working box,big saw,satisfying the requirement of high produce for machine-picked cotton.

4. Adopting saws imported from USA, high output , long use life and good ginning quality.

5. Strengthen the intensity of key parts and rigidity of machine,especially high-intensity running of machine-picked cotton.

6. Intelligent control,rate of safe running over 98%.

7. Scientific and reasonable machine structure,convenient maintenance,adopting many kinds of new technology and material.

Product Description

MY171-17 model cotton saw gin is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It is equipped with high-quality imported components and its product design concept is aligned with international leading standards. The processed lint cotton exhibits superior quality, low impurity content, excellent form, and possessing strong market competitiveness, thereby creating higher economic value for our customers.

Features

1. Modular design: Some cotton gin adopts modular structure design, easy to maintain and repair. This modular design allows for rapid replacement of individual components, minimizing downtime during maintenance or repair work.

2. Energy Efficiency: Modern cotton gin manufacturers strive to make their equipment energy efficient. This may involve using variable speed drives, energy recovery systems, or optimizing airflow and power consumption.

3. Data monitoring and analysis: Some ginns are equipped with data monitoring and analysis systems. These systems collect data on operational parameters such as throughput, fiber quality and energy consumption, enabling operators to optimize performance and eliminate any issues.

Technical Specification

Model | MY171-17 |

Designed output(kg/h) | 1400-2300 |

Equipped power(kw) | 87.85 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 171 |

Diameter of saws(mm) | Φ406 |

Saw spacing(mm) | 17 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 3400*4330*3320 |

Machine weight(kg) | 8000 |

Packing and Delivery

Customized method of packing for buyers available.

(1). Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(2). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

1. Sampling and testing: A systematic sampling plan was developed to collect cotton samples at all stages of the initiation process. These samples are then tested in the laboratory to assess parameters such as moisture content, impurity content, and fiber properties.

2. Record and analyze data: record quality control measurements, test results and any deviations from established standards in detail. This data is analyzed regularly to identify trends, patterns, and areas for improvement.

3. Implement corrective action: If any deviation or problem is found, take corrective action immediately. This may include adjusting starting parameters, inspecting and calibrating equipment, or enhancing operator training.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.