Automatic Cotton Ginning Machines

1. Designed for seed cotton processing, widely used in processing of hand-picked cotton and machine-picked cotton.

2. Special pre-cleaning structure for natural grading and screening of seed cotton.

3. Processing based on the cotton situation, minimizing mechanical damage to the seed cotton, keeping the lint and cotton seed in native state after ginning.

4. Adopting large work box and large saw spacing, cotton roll being of proper tightness degree, natural separation of fibers from cotton seed, keeping the natural look and original length of lint to the maximum, ensuring cotton seed to be intact.

5. Special work box structure, flexible and convenient to open or close, free adjustment of motes rate.

Product Introduction

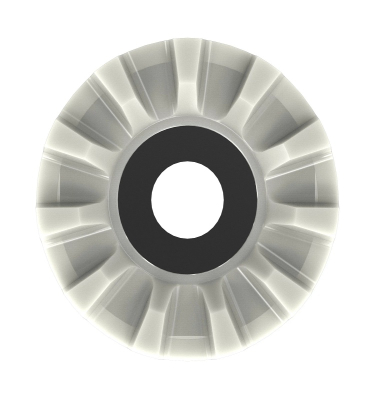

MY126-19.5 model cotton ginning machine is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It adopts high-quality imported components and the product design concept is in line with the leading international standards. The processed lint is of high quality, low impurity content, beautiful shape and has strong market competitiveness, thus creating higher economic value for customers.

Technical Specification

Model | MY126-19.5 |

Designed output(kg/h) | 800-1300 |

Equipped power(kw) | 51.62 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 126 |

Diameter of saws(mm) | Φ320 |

Saw spacing(mm) | 19.4 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 3232*3670*3654 |

Machine weight(kg) | 5200 |

Technical Team

Always at the forefront of technological advancement, Swan has strategically located four production and R&D bases in Montgomery, USA, Jinan, China, Xinjiang and Inner Mongolia. These bases are Swan's strategic factories and laboratories in different regions, aiming to meet diversified market demands and improve technological innovation and product development capabilities.These production and Research & Development (R&D) bases are not only equipped with advanced production equipment and laboratory facilities, but also bring together a highly skilled R&D team. Swan's R&D team consists of engineers, designers and scientists with rich industry experience and professional knowledge, dedicated to technological innovation and product development.

Through the layout of these production and R&D bases, Swan is able to better meet the needs of different regional markets, strengthen its technological innovation and product development capabilities, and provide quality products and services.

Q&A

1. Q:Are you a factory or trading company?

A:We are a factory, and have our own manufacturing bases.

2. Q:Where is your factory Located? How can l visit there?

A:Our factory is located in Jinan, Shandong Province, China. It is about 2 hours flight from Guangzhou. It takes only one and a half hours by high-speed train from Beijing. We warmly welcome your visit with open arms.

3. Q:How does your factory do regarding quality control?

A:Swan first passes ISO9001 quality system authentication in the domestic industry and gains three approval certificates of international quality guarantee system CNACR, RAB, RVA (China, USA, Holland) and the multilateral recognition of world 20 countries.

4. Q:What is your payment terms?

A:Negotiable. T/T In advance, or IRRREVOCABLE LC

5. Q:What is your lead time?

A:Within 20-50 days after receiving the original deposit or letter of credit If you have any other questions or needs, please feel free to contact us, we will reply you as soon as possible.