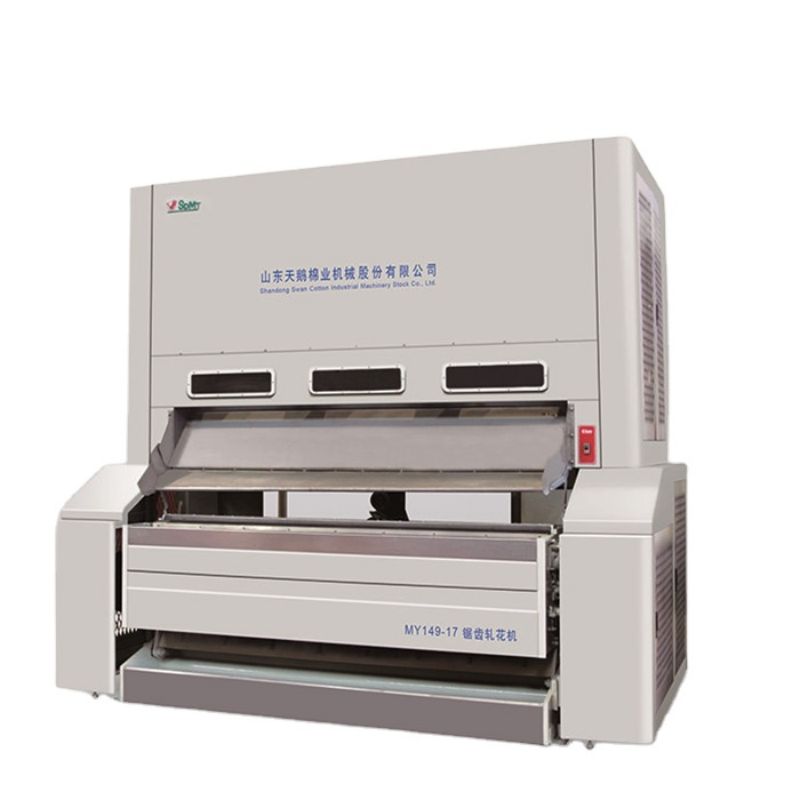

Automatic Cotton Ginning Equipment

1. New structure for the upper part; seed cotton being fully cleaned and opened, good effect on trash removing, cotton moving down evenly, small stress on seed cotton, reducing the spread of dust, improving working environment.

2. Automatic control, particularly stable performance, with safe operation rate not less than 98%.

3. Adopting technology of middle box discharging seeds, strong adaptability to the processing of high moisture cotton, energy saving.

4. Scientific and reasonable machine structure, adopting many kinds of new technology and material.

5. Adopting streamlined close protection cover of specialized processing, safety and environment protection.

6. Many stands flexibly form a complete set and may build saw ginning production lines of different scales.

Product Introduction

Cotton ginning machine MY149-17 is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It uses high quality imported components, product design concept in line with international leading standards.The processed lint has high quality, low impurity content and beautiful shape, which has strong market competitiveness and thus creates higher economic value for customers.

The cotton ginning process begins by feeding harvested cotton into the machine. The cotton gin typically consists of a hopper or feeder that receives the raw cotton. From there, the cotton passes through a series of saw-toothed blades or rotating drums, known as gin stands. These gin stands have small hooks or teeth that grip the cotton fibers, pulling them away from the seeds.

As the cotton fibers are ginned, the seeds, leaves, and other impurities are collected separately. The cotton fibers, also known as lint, are cleaned and guided through extraction mechanisms that remove any remaining debris. The cleaned cotton lint is then collected for further processing, such as spinning and weaving.

Features

1.Safety Features: Cotton gins are equipped with safety features to protect workers and prevent accidents. These features may include emergency stops, guards, and sensors that detect and prevent any abnormal operation.

2.Modular Design: Some cotton ginning machines are designed with a modular structure that allows for easier maintenance and repair. This modular design enables quick replacement of individual components, minimizing downtime during maintenance or repair work.

3.Energy Efficiency: Manufacturers of modern cotton ginning machines strive to make their equipment energy-efficient. This may involve using variable speed drives, energy recovery systems, or optimizing airflow and power consumption.

4.Data Monitoring and Analysis: Some cotton ginning machines are equipped with data monitoring and analysis systems. These systems collect data on operational parameters, such as throughput, fiber quality, and energy consumption, allowing operators to optimize performance and troubleshoot any issues.

5.Size and Capacity: Cotton ginning machines come in different sizes and capacities to cater to various production needs. The capacity can range from small-scale machines suitable for smaller cotton farms to large-scale industrial gins capable of processing massive amounts of cotton.

Technical Specification

Model | MY149-17 |

Designed output(kg/h) | 800-1300 |

Equipped power(kw) | 51.62 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 126 |

Diameter of saws(mm) | Φ320 |

Saw spacing(mm) | 19.4 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 3232*3670*3654 |

Machine weight(kg) | 5200 |

Overseas Marketing

In recent years, Swan has not only established a leading position in the domestic market but has also successfully exported its products to 34 countries and regions, covering major cotton-producing areas in Central Asia, Brazil, Africa, and more. Swan's products are increasingly becoming the preferred choice for overseas users due to their stable performance and exceptional quality. In the future, Swan will continue its dedication to the research, development, and manufacturing of cotton machinery products, aiming to create even greater value for our customers.

Q&A

1. Q:Are you a factory or trading company?

A:We are a factory, and have our own manufacturing bases.

2. Q:Where is your factory Located? How can l visit there?

A:Our factory is located in Jinan city, Shandong province China. About 2 hours flight from Guangzhou. One and half hour by high speed train from Beijing. We are open our arms and warmly welcome you to visit us.

3. Q:How does your factory do regarding quality control?

A:Swan first passes ISO9001 quality system authentication in the domestic industry and gains three approval certificates of international quality guarantee system CNACR, RAB, RVA (China, USA, Holland) and the multilateral recognition of world 20 countries.

4. Q:What is your payment terms?

A:Negotiable. T/T In advance, or IRRREVOCABLE LC

5. Q:What is your lead time?

A:Within 20-50 days after receiving deposit or original LC If you have any other question or demand,please feel free to contact us, we will reply you soon.