Maize Harvesting Machine

1. Cutting table optimized, using knife type picking: no damage to corn, higher efficiency, more durable, lodging corn can be harvested, complete straw crushing treatment at the same time.

2. Using the walking standard hydrostatic four-wheel drive device, transmission with 30 tons of electric shift gearbox, simple and convenient operation, faster walking speed, stronger ability of climbing and get out of the trouble.

3. Widen the wheel base, increase and highten tires, and reduce the center of gravity of the vehicle: walking is more stable and the operation is more suitable for a wider area.

4. Advanced single longitudinal axial flow threshing technology, low damage rate, good separation effect. Axial flow roller adopts electric regulation, stepless speed regulation, easy to operate.

5. Powered by Cummins six-cylinder 300 HP engine: powerful, faster operation, adopt the best transmission ratio, saving average fuel consumption.

6. Standard with three kinds of threshing concave plate, two kinds of separation concave plate, two kinds of cleaning screen, can achieve a variety of crops harvest, truly realize a multi-purpose machine.

7. Using double fish scale screen and cross flow fan cleaning design, cleaning effect is good, clean grain, do grain leakage.

8. Luxury driving cab, at the same time adopt suspension cushioned seat, integrated operation plateform, simple and comfortable.

9. With the bridge reversal function, can achieve feeding reversal when the material blocked , greatly reducing the work intensity of maintenance.

10. The whole vehicle is equipped with one-click oil injection and self-lubricating function.

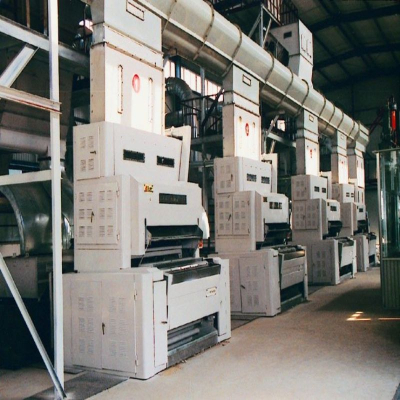

Products Introduction

Shandong Swan 4500 grain combine harvester is a harvester that can complete the process of harvesting, threshing, separating straw, removing impurities, etc., and harvest grain directly from the field. High labor production efficiency, low failure rate, suitable for large-scale grain growing areas.

Product Details

(1). The cutting table allows multiple options depending on cropping patterns and harvested straw handling requirements.

(2). Cummins 6-cylinder 300 hp engine: powerful, faster working speeds with optimal ratios to save on average fuel consumption.

(3). Vehicle Frame

The frame is made of high-end cotton picker material and adopts mortise and tenon welding process to ensure no deformation, no cracking and no breakage.

(4). Front Axle

It is equipped with an electronically shifted transmission and an integrated front drive axle with a capacity of up to 30 tons.

(5). Rear Axle

The four-wheel drive utilizes "one pump, three motors", each of which operates independently, greatly improving the ability to get out of trouble.

(6). Luxury Cab

Air conditioning comes standard and features a suspended padded seat and an integrated operator's console for simple comfort.

Technical Specification

Item | Unit | 4500 |

Harvesting rows | row | 12KG/S |

Application scope of row space | mm | |

Power of engine | KW(HP) | 221(300HP) |

Working efficiency | h㎡/h | Around 2 |

Volume of tank | m³ | 9 |

Height of unload | mm | 5100 |

Weight | kg | 15000 |

Overall size(L×W×H) | mm | 9500×6100×4300 |

Type of walk | hydraulic four-wheel drive |

Special Transportation Design

According to the previous delivery experience, there are certain differences in the structure and size of the grain harvester and the conventional equipment. Therefore, in cross-border transportation, we will use special packaging and packing schemes to ensure product safety and no damage.

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1) . Functional test: Check whether the function of the product is working properly. This can be done by operating the product for functional testing.

(2) . Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on.

(3). Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4). Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

Features

1. Cutting corn stalks: Corn harvesters are equipped with special tools and cutting systems that can quickly cut off the stalks of corn plants. This facilitates subsequent handling and collection of ears of corn.

2. Gather ears of corn: Corn harvesters will collect, clean and treat cut corn plants. It usually includes a collection box or grain hopper for temporary storage and storage of harvested ears of corn.

3. Treatment of ridge crops: Corn harvester also has the ability to deal with ridge crops. It can separate waste and weeds from harvested corn during the treatment process, reducing the proliferation of weeds in arable land.

Company Information

Shandong Swan Cotton Industrial Machinery Co., Ltd. is a listed company under Shandong Supply and Marketing Cooperative. Its predecessor was established in 1946.Set scientific research and development, precision production, marketing services, capital operation as a whole, specializing in mechanization, intelligent, information-based cotton processing equipment to provide one-stop supply and services, products are exported to more than 30 countries. The domestic market share has topped the list for several consecutive years. Marketing services network throughout the world's major cotton producing areas.

With cotton machinery as the main business, the company strives to promote the transformation and upgrading of cotton industry, create a new era of intelligent factory, create the first brand of global cotton machinery, actively expand to the intelligent agricultural machinery equipment industry, and fully stride into the high-end equipment manufacturing industry.

Shandong Swan Cotton Machinery Co., Ltd. has four technical centers and production bases in Jinan, Shandong, Wujia.Xinjiang, Hailar, Inner Mongolia and Montgomery, three national high-tech enterprises and six provincial innovation platforms, leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Plan for Scientific and Technological Achievements", and the undertaking unit of "13th Five-Year Plan" National key R&D Plan.