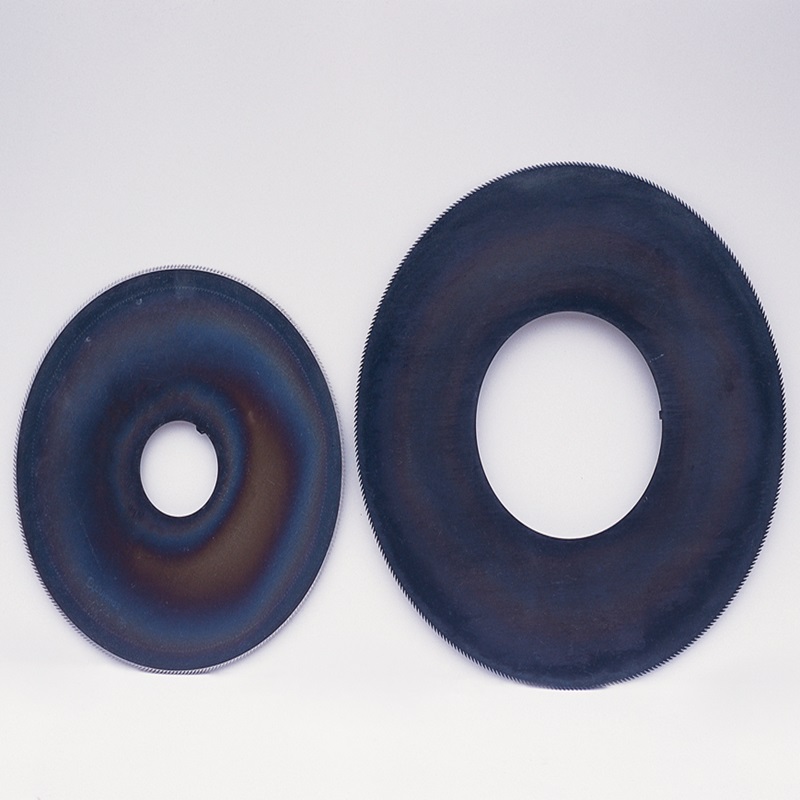

Gin Saw Blades

1. Adopt imported material from USA, high intensity, good toughness and long working life.

2. Even thickness, smoothness, good lint quality and less neps.

3. Variable patented teeth design for different processing conditions, strong adaptation.

4. φ406 saw is made by Shandong Swan USA, Inc., originally imported so as to guarantee the quality.

Product Introduction

The Swan brand ginning and delinting saws uses imported sheet metal from the United States, which has longer service life and better quality. Using the world's leading automatic saw blade manufacturing machine, the production precision is high, the quality is stable, can adapt to the production needs of different customers. High production efficiency and orders delivery is more timely. Safe and environmental protection, no pollution.

Technical Parameter

Model Size | Ginning Saws 406 | Ginning Saws 320 | Delinting Saws 320 |

Qty of Saws | 330 | 304 | |

External Dia. | 406 | 320 | |

Internal Dia | 174.6 | 74.6 | |

Surface hardness | 35 | ||

Surface Planeness | 0.4 | ||

Packing and Delivery

Packing Method:

Waterproof paper + plastic film or customized for buyers.

(1) The mode of transportation is flexible and changeable, and different modes of transportation can be adopted according to the needs of customers.

(2) The packaging material is strong and durable, and can adapt to international long-distance transportation.

(3) Customer-oriented, customizable packaging.

Product Inspection

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1). Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on. This can be done by visual inspection or using auxiliary tools (e.g. microscopes, measuring instruments).

(2). Size and weight testing: Measure the size and weight of the product and compare it with the design specifications to ensure that it meets the requirements. This can be done by using measuring instruments, scales and other equipment.

(3). Material and component testing: Check whether the materials and components used in the product meet the requirements. This can be done by chemical analysis, spectral analysis, tensile testing and other methods.

(4). Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

FAQ

1.Q:Are you a factory or trading company?

A:We are a factory, and have our own manufacturing bases.

2.Q:Where is your factory Located? How can l visit there?

A:Our factory is located in Jinan city, Shandong province China. About 2 hours flight from Guangzhou. One and half hour by high speed train from Beijing. We are open our arms and warmly welcome you to visit us.

3.Q:How does your factory do regarding quality control?

A:Swan first passes ISO9001 quality system authentication in the domestic industry and gains three approval certificates of international quality guarantee system CNACR, RAB, RVA (China, USA, Holland) and the multilateral recognition of world 20 countries.

4.Q:What is your payment terms?

A:Negotiable. T/T In advance, or IRRREVOCABLE LC.

5.Q:What is your lead time?

A:Within 20-50 days after receiving deposit or original LC.