Cotton Seed Delinting Machine

1. The newly designed work box runs more smoothly.High rate of lint output and low rate of residual fleece and broken seed.

2. Adopt new trapezoidal rib, increase the strength of rib, plating treatment to make rib smooth without hanging velvet.

3. The opening and closing of the working box adopts hydraulic structure, and the action is stable without impact when opening and closing the box.

4. Automatic loading and unloading of saw cylinder, reducing labor and labor intensity.

5. Saw cylinder life cycle management, automatic reminder to replace the saw cylinder.

Product Introduction:

The saw delinting machine is mainly used for the delinting of cotton seeds in ginning factory or oil extraction plants. Its main function is to make the cotton seeds enter the working box of the delinting machine and be scraped by the rotating saw blade under the barrier of the rib to achieve the purpose of separating cotton seeds and short fiber. Our product types are rich, and we can configure suitable product models according to different processing needs of customers.

Main parameters:

Model Parameter | MR-144D | MR-164M | MR-164S | MR-161 | MR-178 | |

Seedcotton processing capacity (kg/h) | First time | 3500-4500 | 3500-4500 | 4000-4500 | 4000-5500 | |

Second time | 1000-1500 | 900-1100 | 1200-1500 | 1300-1800 | ||

Third time | 750-1000 | 900-1100 | 950-1200 | |||

Saw diameter(mm) | Φ320 | Φ320 | Φ320 | Φ320 | Φ406 | |

Power(kw) | 24.35 | 27.85

| 54.95

| 31.35+

| 31.35+

| |

Overall dimension(L*W*H)(mm) | 2600X1880X2000

| 2650x1950X1970

| 2650x1950X2480

| 2560x1320X2000

| 2970x1400X2040

| |

Weight(kg) | 2500

| 1800

| 3500

| 3000

| 4000

| |

Note | The above output refers to the output when the residual lint rate and short lint quality of standard grade cottonseed with water content less than 10% are processed. | |||||

Product Features:

1.The newly designed work box runs more smoothly.High rate of lint output and low rate of residual fleece and broken seed.

2. Adopt new trapezoidal rib, increase the strength of rib, plating treatment to make rib smooth without hanging velvet.

3. The opening and closing of the working box adopts hydraulic structure, and the action is stable without impact when opening and closing the box.

4. Automatic loading and unloading of saw cylinder, reducing labor and labor intensity.

5. Saw cylinder life cycle management, automatic reminder to replace the saw cylinder.

6. Saw cylinder bearing seat adopts double pressure plate structure, which can realize fast disassembly.

7. With double lint suction structure, the short fiber is easy to suck away.

8. The amount of seed feeding is automatically adjusted to achieve the optimal working state, and the processing is more energy saving.

9. Rack and pinion structure is adopted for the adjustment of the cotton seed comb, which is easy to operate and ensures the same gap.

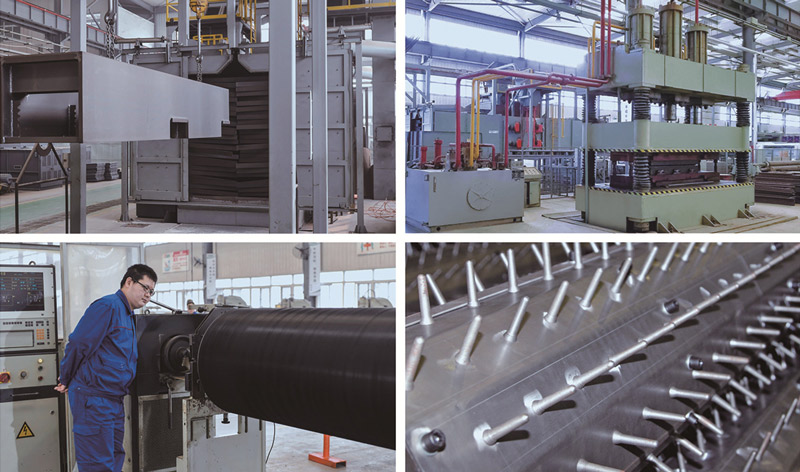

Product Inspection:

Shandong Swan Cotton Industrial Machinery Stock Co.,Ltd will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1) Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on. This can be done by visual inspection or using auxiliary tools (e.g. microscopes, measuring instruments).

(2) Functional test: Check whether the function of the product is working properly. This can be done by operating the product, performing functional tests, or using specific test equipment to verify the performance and functionality of the product.

(3) Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4) Material and component testing: Check whether the materials and components used in the product meet the requirements. This can be done by chemical analysis, spectral analysis, tensile testing and other methods.

Packing and Delivery:

Packing Method:

Plastic film+waterproof paper or customized for buyers.

(1) Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(2) The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3) Cooperate with reliable shipping company, key time nodes are updated in real time.

Company Strength:

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.

Customer visit