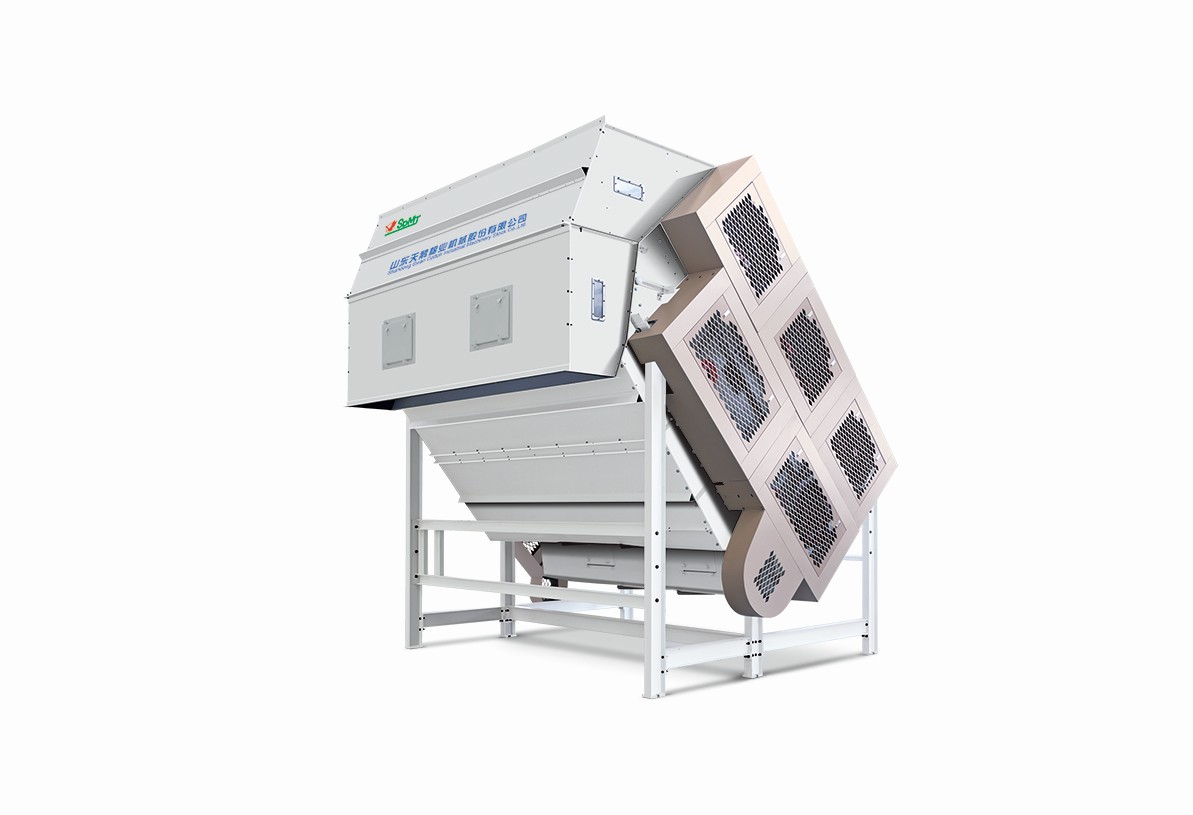

Row Cotton Pre-Cleaning Machine

1. This machine has two parts : upper part and lower part which can be used as a whole and also can be used separately.

2. One machine serves several purposes which reduces erection height,saves space and cast for equipment investment and erection.

3. The structure of upper and lower parts is independently designed so as to increase trash discharge rate and reduce cotton loss.

4. The structure of barbed nail cylinder adopts 14-edged patented design, good stability, little vibration and trash discharge rate is not less than 65%.

5. Barbed nail is processed by CNC machining center , taper ball head design, little damage to fiber, uneasy to jam.

6. Visible protection cover adopts uses advanced phosphating process and plastic powder coating technology, strong adhesion, corrosion resistance ,oxidation resistance and elegant appearance.

Product Introduction

Double-deck Hierarchical Type Seed cotton Cleaner is a kind of equipment used for cotton processing, mainly used to clean up impurities in cotton and seed cotton. It has the advantages of good cleaning effect and simple operation. It can improve the quality and clarity of cotton at the same time can reduce the workload and cost of manual cleaning, improve production efficiency.

Scope of Application

Mainly used to clean machine-picked cotton , manual fast-picked cotton and hand-picked cotton.

Technical Specification

Model | Capacity(kg/h) | Power(kW) | Overall Dimension (LxWxH)(mm) | Weight(kg) |

MQZF-15 | 13000~15000 | 44 | 4310x4222x4247 | 13000 |

MQZF-12 | 10000~12000 | 37 | 3860x4222x4247 | 12000 |

MQZF-10 | 8000~10000 | 30 | 3100x4177x4247 | 11500 |

Note | The above capacity means processing capacity of standard grade seed cotton whose moisture rate is not more than 7% and ginned lint reaches quality standard. | |||

Packing and Delivery

1. Preparation: Prepare all necessary packing materials, such as strong cartons, bubble wrap, packing peanuts, packing tape, shipping labels, etc.

2. Disassemble and clean: If possible, disassemble any removable parts of the cottonseed cleaner to reduce its overall size and make it easier to pack. Clean the machine thoroughly before packing to remove any dirt or debris.

3. Protect fragile parts: Wrap fragile or easily damaged parts, such as blades or sensors, with bubble wrap or foam filler. Secure the package with tape to keep it in place.

4. Secure the machine: Place the cottonseed cleaner in a sturdy carton slightly larger than the machine. Use packing peanuts, bubble wrap or foam filler to fill any gaps and provide cushioning around the machine.

5. Box sealing: The box is sealed tightly and the joints are reinforced with packing tape to ensure that it is intact during transportation. Make sure there are no loose or exposed parts that could break or cause damage during transportation.

6. Label and documentation: Clearly label the package with the recipient's address and contact information, as well as your own return address. Include any necessary shipping documents such as invoices or customs documents if shipping internationally.

Product Inspection

1. Documentation and Certification: Check that the machine comes with the necessary documentation, including manuals, operating instructions, and maintenance guidelines.In addition, it is also necessary to check whether there are relevant certifications or industry standards to verify the quality and safety of the machine.

3. Safety check: Before packing and shipping, we will try the machine to ensure the normal operation of the machine

4. Warranty and after-sales service: if there are quality problems in the use process, we can guarantee it. In addition, we provide installation instructions

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.