Cotton Processing Online Test&Intelligent Control System

1. Adapt automatic cotton feeding and overflow system, steady and continuous feeding of enough seed cotton,excess seed cotton goes into overflow system, can meet the needs of large scale production line, to ensure the design capacity of the production line. At the same time reduce the manual working intensity,reduce the outage rate due to lacking of cotton feeding.

2. The production line is equipped with automatic bag loader, which reduces the working frequency of forklift truck, saves fuel, reduces labor and improves safety performance.

3. Surveillance video,set up HD camera in the place of workshop feeding, bale press cotton convey , sterile seed baling,cotton seed out of workshop, cotton seed cleaner etc. At the same time, a 55-inch large screen is fixed between the gin machines to facilitate the observation of production conditions.

4. High degree of automation of the production line, less labor, the whole production line only needs 9 operators (1 person for pit feeding, 2 people for ginning and lint cleaner, 1 person for operating, 3 people for baling machine, 1 person for bag loader, 1 person for packing sterile seeds).

5. Factory production, block type lap, save installation time and cost.

Product Introduction:

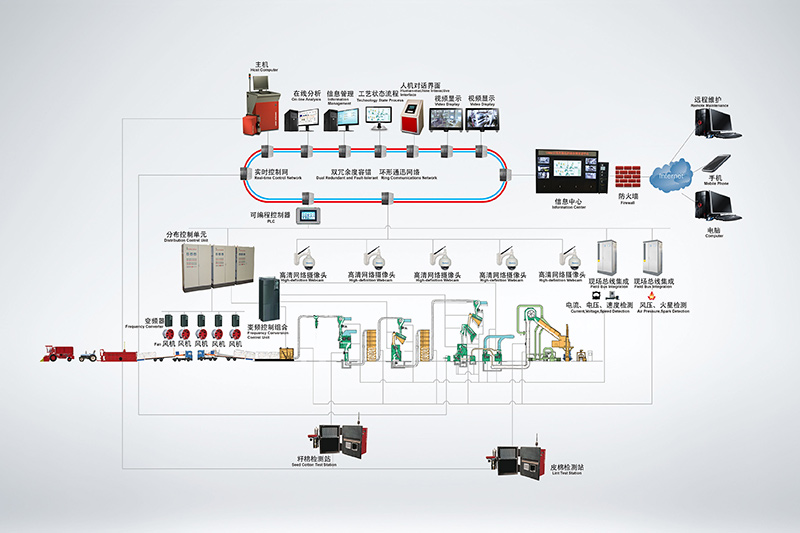

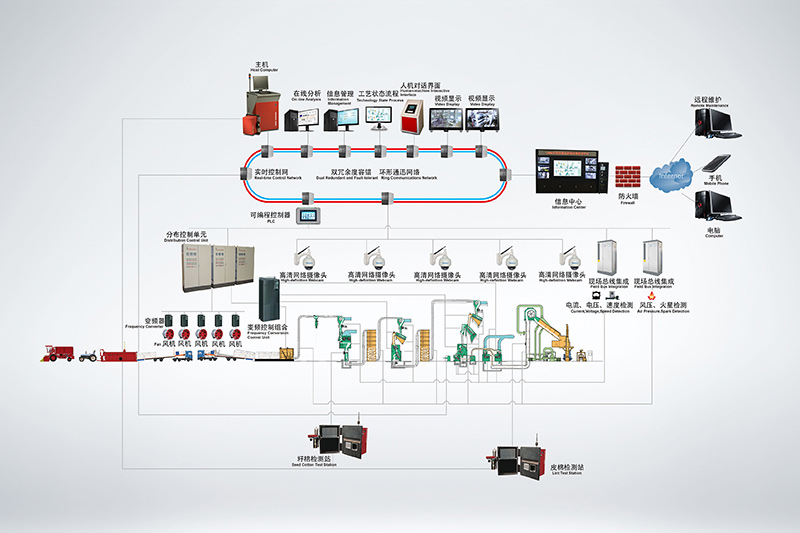

Cotton processing quality on-line monitoring, intelligent control system.

The integration of international top technology, real-time online detection of cotton processing quality index, automatic optimization and adjustment of processing technology, truly realize the long-term pursuit of the industry "equipped with machinery due to cotton" processing concept. Quality indexes such as impurity, water content and color grade of seed cotton and lint were tested online, according to this information, the best processing plan is adjusted in time, and different cotton processes and equipment configuration parameters are used to improve the quality of lint.

On-line monitoring system:

The main quality parameters of seed cotton and lint were tested online by using the same technology and monitoring standard as HVI monitoring equipment. Real-time acquisition of digital signals and video signals in the production process, and analysis and processing, in order to control the operation of equipment, adjust at any time.

Regulatory executive system:

Automatic adjustment of equipment parameters and processes according to the optimized processing plan provided by the intelligent analysis system.

Information management system:

The collection, analysis and processing of all kinds of information data of production line provide conditions for fine calculation of gin mill. To realize timely collection of information related to multiple production lines, facilitate resource sharing and optimize management.

Remote maintenance support system:

Provide remote technical support and services through secure and reliable communication channels

Intelligent analysis system:

The on-line monitoring of cotton quality information is automatically compared with the set target value to provide an optimized processing plan at any time.

Safeguard system:

A complete set of intelligent protection devices to ensure the safety of people and equipment, eliminating fire, personal injury and other safety hazards.

Energy saving system:

On-line automatic adjustment of the whole power system, high efficiency and energy saving.

Company Strength:

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.

Customer visit