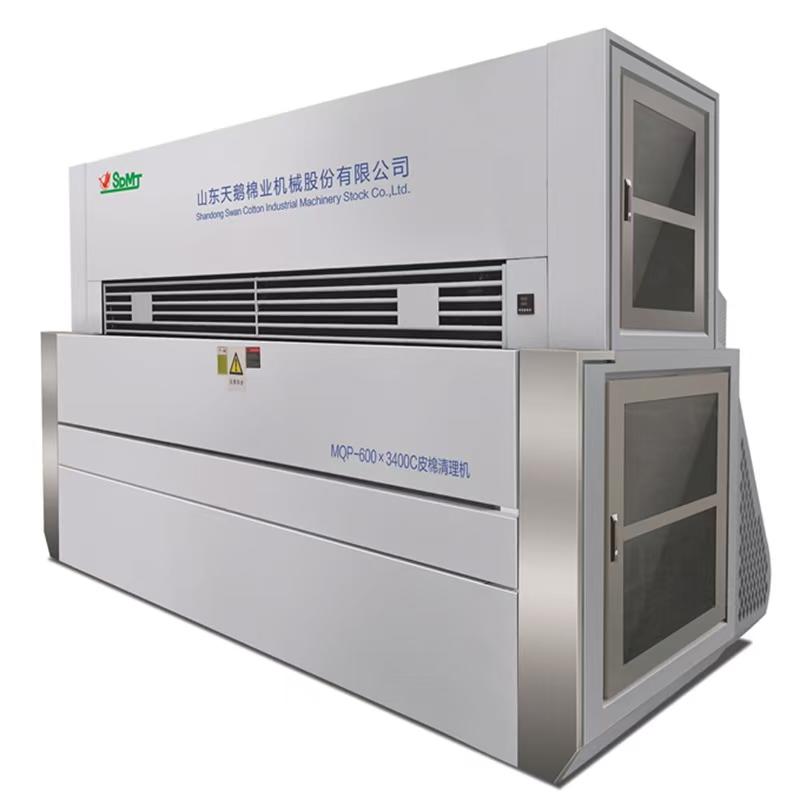

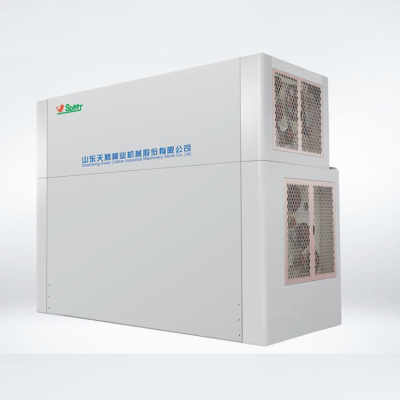

Saw Type Lint Cleaner MQP-630

1. Whole machine adopting many kinds of special material, reasonable structure, steady and reliable performance.

2. Teeth bar adopting special material and teeth shape, long service life, good cleaning result and little damage to fiber.

3. Discharge knife for foreign matter of special structure ensuing effectively reduce fiber loss at the same time removing foreign matter to a maximum.

4. Advanced pressing, stripping and feeding structure, reducing fiber damage and failure rate of equipment.

5. Adopting new structure of carding cotton feeding roller and fixed feeding point, steady carding, which can solve the phenomenon of discharging “white cotton".

6. Discharge area of discharge knifes are reasonable allocated, improve the cleaning result and lint quality.

Product Introduction

Saw-type lint cleaners are commonly used to improve the overall quality of ginned lint by removing foreign matter and less desirable short fiber after ginning. Swan’s lint cleaner with the characteristic of stable performance, high level product quality and enhancing the quality of the lint remarkably.

Main Technical Parameters

Model Parameter | Prick roller diameter(mm) | Designed output(kg/h) | Equipped power(kw) | Overall dimension(mm) | Weight(kg) | ||

MQP-400x2000H | Φ400 | 1000~1800 | 19 | 2800x1325x2285 | 3400 | ||

MQP-400x2500H | Φ400 | 1300~2100 | 22.5 | 3300x1325x2295 | 4500 | ||

MQP-400x3400H | Φ400 | 2400~3600 | 37.5 | 4300x1510x2295 | 7000 | ||

MQP-600x2000H | Φ600 | 1200~2000 | 22.5 | 2800x1600x2615 | 4100 | ||

MQP-600x3000H | Φ600 | 2400~3600 | 27.5 | 3750x1660x2615 | 6600 | ||

Note | The above output is for the standard grade seed cotton with the moisture rate Between 6.5%~8.5%. | ||||||

Packing and Delivery

(1).We have an experienced packaging and loading team that can ensure the safety and integrity of goods during packaging and transportation.

(2). Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(3). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(4). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

(1).Functional test: Check whether the function of the product is working properly. This can be done by operating the product for functional testing or by using specific test equipment to verify the performance and functionality of the product.

(2).Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

(3).Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4).Material and component testing: Check whether the materials and components used in the product meet the requirements. This can be done by chemical analysis, spectral analysis, tensile testing and other methods.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production, marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized, intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA, three national high-tech enterprises and six provincial innovation platforms, leading the technological progress of the industry for many years. It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.

FAQ

1.Q:Are you a factory or trading company?

A:We are a factory, and have 4 our own manufacturing bases in headquarter Jinan, Xinjiang, Inner Mongolia and America Montgomery.

2.Q:Where is your headquarter Located? How can l visit there?

A:Our headquarter is located in Jinan city, Shandong province China. About 2 hours flight from Guangzhou. One and half hour by high speed train from Beijing. We are open our arms and warmly welcome you to visit us.

3.Q:How does your factory do regarding quality control?

A:Swan first passes ISO9001 quality system authentication in the domestic industry and gains three approval certificates of international quality guarantee system CNACR, RAB, RVA (China, USA, Holland) and the multilateral recognition of world 20 countries.

4.Q:What is your payment terms?

A:Negotiable. T/T In advance, or IRRREVOCABLE LC.

5.Q:What is your lead time?

A:Within 20-50 days after receiving deposit or original LC. If you have any other question or demand, please feel free to contact us, we will reply you soon.