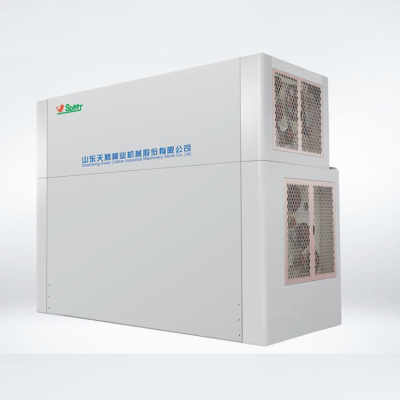

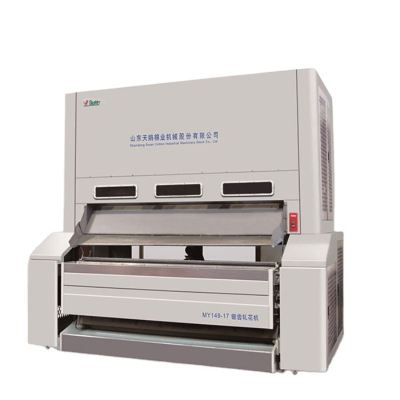

Air-jet Cotton Lint Cleaner

1. Whole machine adopting many kinds of special material,reasonable structure, steady and reliable performance.

2. Series of air-jet type lint cleaners have the characteristics of no power consumption breakdown easy adjustment and installation, beautiful appearance, high efficiency of cleaning without fiber damage. etc.

Product Introduction

Air-jet type lint cleaner are commonly used to improve the overall quality of ginned lint by removing foreign matter and less desirable short fiber after ginning. Swan’s lint cleaner with the characteristic of stable performance,high level product quality and enhancing the quality of the lint remarkably.

Technical Specification

Model Spec | Designed output(kg/h) | Equipped power(kw) | Overall dimension(mm) | Weight(kg) |

MQPQ-3300 | 3300(Lint) | 3555x1282x1485 | 3555x1282x1485 | 320 |

MQPQ-3000 | 3000(Lint) | 3555x1282x1485 | 3555x1282x1485 | 300 |

MQPQ-2000 | 2000(Lint) | 2255x1282x1485 | 2255x1282x1485 | 260 |

MQPQ-1400 | 1800(Lint) | 1655x1282x1485 | 1655x1282x1485 | 230 |

Packing and Delivery

(1).We have an experienced packaging and loading team that can ensure the safety and integrity of goods during packaging and transportation.

(2). Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(3). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(4). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

(1).Functional test: Check whether the function of the product is working properly. This can be done by operating the product for functional testing or by using specific test equipment to verify the performance and functionality of the product.

(2).Label and instruction manual inspection: Check whether the label and instruction manual of the product are accurate, clear, complete, and comply with the relevant regulations and standards.

(3).Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4).Materials and components inspection: check whether the materials and components used in the product meet the requirements. This can be done by chemical analysis, spectral analysis, tensile test and other methods.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company under Shandong Supply and Marketing Cooperative. Its predecessor was established in 1946.Set scientific research and development, precision production, marketing services, capital operation as a whole, specializing in mechanization, intelligent, information cotton processing equipment to provide one-stop supply and service, products are exported to more than 30 countries.Its domestic market share has topped the list for several consecutive years. Marketing services network throughout the world's major cotton producing areas.

With cotton machinery as the main business, the company strives to promote the transformation and upgrading of the cotton industry, create a new era of intelligent factories, build the first brand of cotton machinery in the world, actively expand to the intelligent agricultural machinery equipment industry, and comprehensively enter the high-end equipment manufacturing industry.

Shandong Swan Cotton Machine Co., Ltd. has four technology centers and production bases in Jinan, Shandong, Wujiaqu, Xinjiang, Hailaer, Inner Mongolia, Montgomery, United States, three national high-tech enterprises and six provincial innovation platforms, leading the technological progress of the industry over the years.It is a high-tech enterprise in Shandong Province, technical support unit of "National Key Promotion Plan for Scientific and Technological Achievements", and undertaking unit of "13th Five-Year Plan" national key Research and Development Plan.