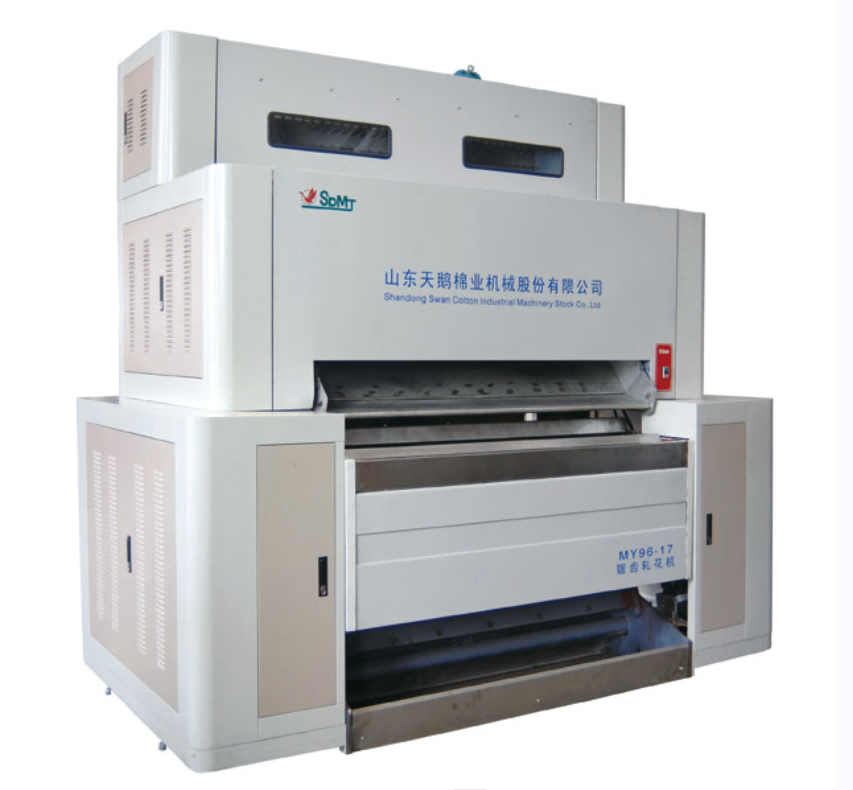

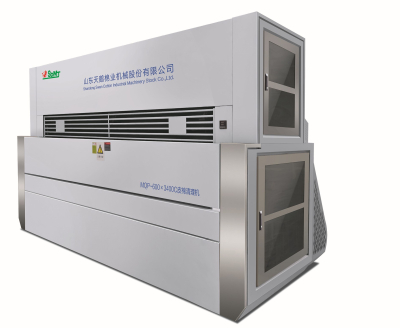

Stable cotton ginning machine good quality good price saw gin

Technical Features

1. Cleaning section adopts non-concentric structure which realizes Jitter cleaning of seed cotton.

2. Cleaning efficiency is not less than 50% , no damage to fiber.

3. Recovery roller can efficiently recover missed cotton which reduces cotton loss.

4. The whole structure is reasonable , easy to adjust, operation and maintenance is also convenient.

Product Introduction

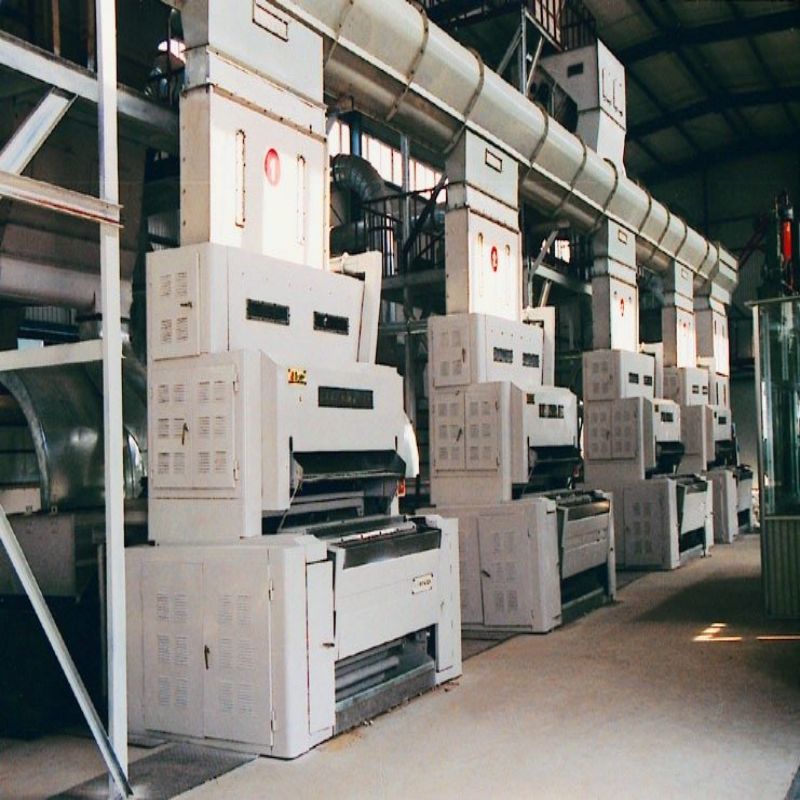

MY96-17 type cotton ginning machine was designed for small ginning factory, depends on the quality of the seedcotton, capacity of it can be 600kg to 1300kg per hour. It mainly use for separating fiber from the seeds and remove impurities from the raw cotton. The whole ginning machine with the characteristics of stable and high efficient.

Technical Specification

Designed output(kg/h) | 600-1200 |

Equipped power(kw) | 46.12 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 96 |

Diameter of saws(mm) | Φ320 |

Saw spacing(mm) | 17 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 2385*2850*2750 |

Machine weight(kg) | 4200 |

Packing and Delivery

Supporting customized method of packing for buyers.

(1). Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(2). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

We will carry out strict comprehensive testing for each factory product, mainly including the following contents:

(1). Appearance inspection: Check whether the appearance of the product meets the requirements, including color, shape, size, surface finish and so on. This can be done by visual inspection or using auxiliary tools (e.g. microscopes, measuring instruments).

(2). Functional test: Check whether the function of the product is working properly. This can be done by operating the product, performing functional tests, or using specific test equipment to verify the performance and functionality of the product.

(3). Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4). Packaging inspection: check whether the packaging of the product is intact, whether the label is clear, and whether the packaging materials meet the requirements. This ensures that the product is not damaged during transportation and storage, and that it can be properly identified and identified.