Saw Ginning Machines

1. Patented product , specially designed for enterprises which pursue high efficiency , only for machine-picked cotton.

2. New extracting and feeding structure , high cleaning efficiency , continuous and even feeding, no flying dust.

3. New working box , high output , good quality.

4. Adopting saws imported from USA, high output , long use life and good ginning quality.

5. New adjustment structure , fiber rate of ginned seeds can be controlled at random.

6. Intelligent control , safe running rate is not less than 98%.

7. Simple and reasonable structure , stable and reliable running , convenient maintenance , new technique and new material.

Product Introduction:

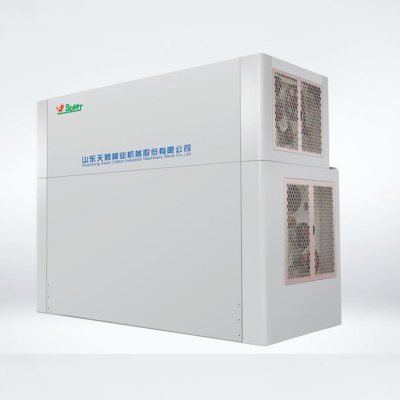

The cotton saw gin with the model of MY199-16 is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It is equipped with high-quality imported components and its product design concept is aligned with international leading standards. The processed lint cotton exhibits superior quality, low impurity content, excellent form, and possessing strong market competitiveness, thereby creating higher economic value for our customers.

Features

1. Seed extraction system: The cotton gin separates the seeds from the cotton fibers.This can be achieved by screening systems, pneumatic conveyors, or gravity mechanisms that direct the seeds to a separate collection chamber.

2. Automatic control: Many modern cotton gins have advanced automation and control systems.These systems monitor and adjust the speed, airflow, and other parameters of the machine to optimize start-up efficiency and reduce fiber damage.

3. Safety features: the gin is equipped with safety devices to protect workers and prevent accidents.These functions may include emergency stops, protective devices, and sensors to detect and prevent any abnormal operation.

Technical Specification

Model | MY199-16 |

Designed output(kg/h) | 2000-3000 |

Equipped power(kw) | 107.25 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 199 |

Diameter of saws(mm) | Φ406 |

Saw spacing(mm) | 16 |

Diameter of brush cylinder(mm) | Φ450 |

Overall dimension(W*L*H)(mm) | 3676*4560*3558.5 |

Machine weight(kg) | 11000 |

Packing and Delivery

Providing customized method of packing for buyers.

(1). Each machine can through container shipped to the port of destination, we put the machine in the container to reinforce, ensure the quality of the product is not damaged.

(2). The whole product loading process and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3). Cooperate with reliable shipping company, key time nodes are updated in real time.

Product Inspection

(1).Appearance inspection: Inspection personnel through visual inspection or the use of auxiliary tools (such as microscopy, measuring instruments), check whether the appearance of the product meets the requirements, mainly including color, shape, size, surface finish, etc.

(2). Functional test: Check whether the function of the product is working properly. This can be done by operating the product, performing functional tests, or using specific test equipment to verify the performance and functionality of the product.

(3). Safety testing: Check whether the product meets the relevant safety standards and regulatory requirements. This can include testing for electrical safety, mechanical safety, chemical safety, etc.

(4). Packing inspection: before shipment inspection Round Baler packing are in good condition, whether the product label is clear, complete, packaging material is in accordance with the relevant requirements.This product can be ensured in the process of transportation and storage is not easy to damage, and can be correctly identify guarantee.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been sold to more than 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.