Modern Cotton Gins

1. New type of cotton extracting and feeding structure, high efficiency on trash removing, cotton moving down continuously and evenly without flying dust.

2. New design parameters for the work box, more conducive to the running of cotton roll, free adjustment of motes rate.

3. Intelligent control, with safe operation rate not less than 98%.

4. Adopting technology of middle box discharging seeds, high output and low power consumption, strong adaptability to the processing of high moisture cotton.

5. Adopting saws imported from America, high output and long life, good ginning quality.

6. Scientific and reasonable machine structure, stable and reliable operation, easy maintenance.

7. Adopting streamlined visual protection cover, safe and environment protection.

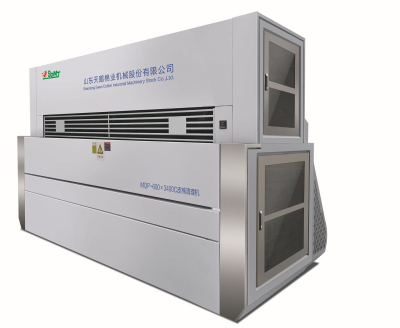

Product Introduction

Model of MY158-17 cotton ginning machine is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It is equipped with high-quality imported components and its product design concept is aligned with international leading standards. The processed lint cotton exhibits superior quality, low impurity content, excellent form, and possessing strong market competitiveness, thereby creating higher economic value for our customers.

Technical Specification

Model | MY158-17 |

Designed output(kg/h) | 1100-1800 |

Equipped power(kw) | 64.75 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 158 |

Diameter of saws(mm) | Φ406 |

Saw spacing(mm) | 17 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 3138*4068*3508.5 |

Machine weight(kg) | 8100 |

Packing and Delivery

Each machine receives excellent support and reinforcement within the shipping container, ensuring its safe arrival at the destination port.

The entire process of product loading and container sealing is documented through photos or videos, offering full visibility and control.

We collaborate with reliable shipping companies and provide real-time updates on key milestones.

Overseas Marketing

In recent years, Swan has not only established a leading position in the domestic market but has also successfully exported its products to 34 countries and regions, covering major cotton-producing areas in Central Asia, Brazil, Africa, and more. Swan's products are increasingly becoming the preferred choice for overseas users due to their stable performance and exceptional quality. In the future, Swan will continue its dedication to the research, development, and manufacturing of cotton machinery products, aiming to create even greater value for our customers.