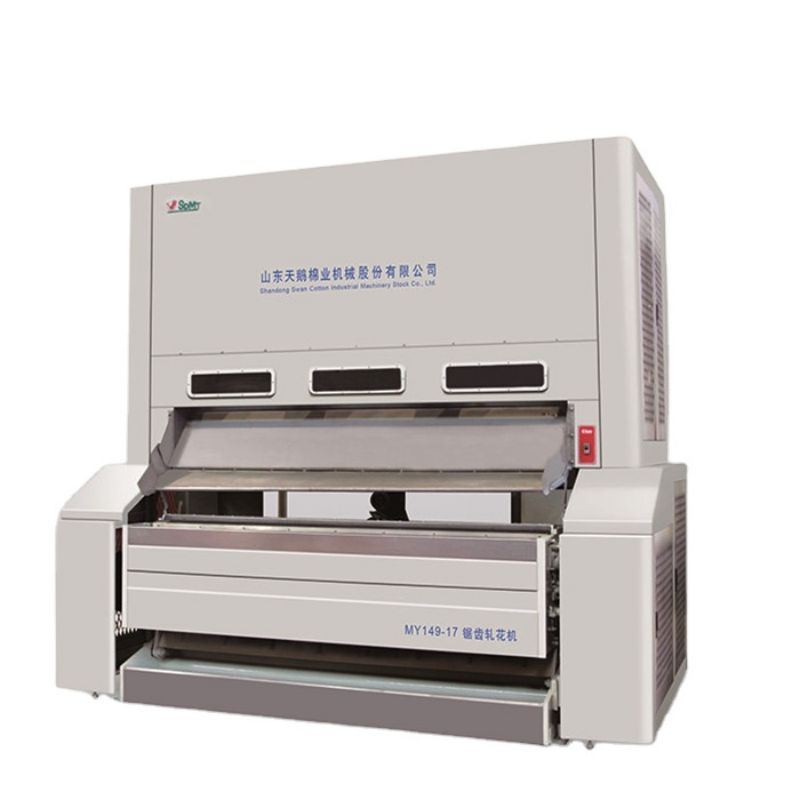

Industrial Cotton Gin

1. New structure for the upper part; seed cotton being fully cleaned and opened, good effect on trash removing, cotton moving down evenly, small stress on seed cotton, reducing the spread of dust, improving working environment.

2. Automatic control, particularly stable performance, with safe operation rate not less than 98%.

3. Adopting technology of middle box discharging seeds, strong adaptability to the processing of high moisture cotton, energy saving.

4. Scientific and reasonable machine structure, adopting many kinds of new technology and material.

5. Adopting streamlined close protection cover of specialized processing, safety and environment protection.

6. Many stands flexibly form a complete set and may build saw ginning production lines of different scales.

Product Introduction

MY149-17 type cotton saw gin is specifically designed for separating fibers from the cotton seeds and cleaning the cotton seeds. It is equipped with high-quality imported components and its product design concept is aligned with international leading standards. The processed lint cotton exhibits superior quality, low impurity content, excellent form, and possessing strong market competitiveness, thereby creating higher economic value for our customers.

Technical Specification

Model | MY149-17 |

Designed output(kg/h) | 800-1300 |

Equipped power(kw) | 51.62 |

Lint ginning quality | Achieved or exceed national standard for ginned cotton of same |

Noise | 90dB(A) |

Pieces of saws(pcs) | 126 |

Diameter of saws(mm) | Φ320 |

Saw spacing(mm) | 19.4 |

Diameter of brush cylinder(mm) | Φ380 |

Overall dimension(W*L*H)(mm) | 3232*3670*3654 |

Machine weight(kg) | 5200 |

Product Inspection

1. Size and weight testing: Measure the size and weight of the product and compare it with the design specifications to ensure that it meets the requirements. This can be done by using measuring instruments, scales and other equipment.

2. Material and component testing: Check whether the materials and components used in the product meet the requirements. This can be done by chemical analysis, spectral analysis, tensile testing and other methods.

3. Sampling testing: Sampling testing of mass-produced products to represent the quality of the entire batch.

Overseas Marketing

Swan's products not only occupy a leading position in the domestic market, but also successfully exported products to 34 countries and regions, covering Central Asia, Brazil, Africa and other major cotton producing areas of the world. Swan products with its stable performance and excellent quality, are increasingly becoming the first choice of foreign users. In the future, Swan will continue to be committed to the development and manufacturing of cotton machine products to create higher value for customers.