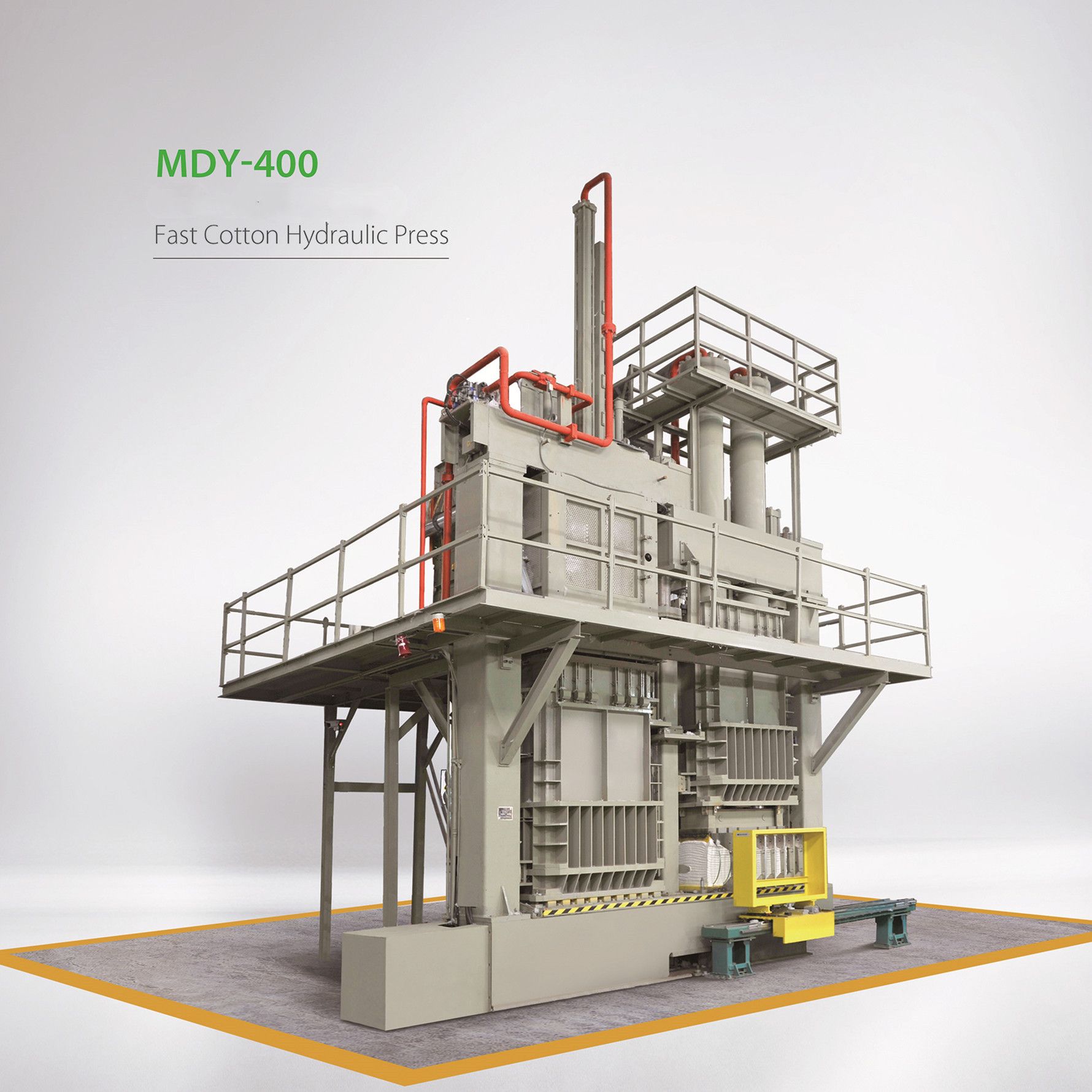

Cotton Press

1. Modular structure, frame connection & pin shaft positioning , strong rigidity , convenient erection and good stability & reliability.

2. High capacity and one-piece cotton box can efficiently solve box expansion during tramping;suction cover structure can avoid fiber flying and dropping.

3. Weighted hooking structure as patented technology , low trouble rate.

4. Box upward process adopts hydraulic step control , impact reduction , auto locking , safety and reliability.

5. Recycling cooling and filtering device , hydraulic system runs stably ;sealing system adopts USA Parker product,no leakage, long using life.

6. Pusher adopts flexible hydraulic control ,less hydraulic impact ;box rotation adopts hydraulic motor and proportional valve control , fast and stable.

7. Signal induction from ram and tramp adopts infinite position adjustment , convenient and accurate;PLC real-time signal collection and control , accurate action , fault automatic display , security hidden danger reduction ,precise measurement and even bale weight.

Product Introduction

The Cotton Bale Press Machine is used in the agricultural industry to compress raw cotton fibers into tightly packed bales for easy transportation, storage, and processing.

The machine is commonly used in cotton processing plants, ginning mills, and agricultural facilities where cotton is harvested. It plays a significant role in increasing efficiency and reducing labor costs in the cotton industry.

Technical Specification

Main Parameters Designed Output(Bales/H) | 20Bales/ 4540kg | 25Bales/ 5675kg | 30Bales/ 6810kg | 40Bales/ 9080kg |

Nominal Work Pressure(kn) | 4000 | |||

Bale Dimensions(mm) | 1400*530*700 | |||

Bale Weight(kg) | 227±10 | |||

Compression Height(mm) | 485-508 | |||

Power(kw) | 85 | 115 | 123 | 153 |

Machine Weight(kg) | 45000 | |||

Technical Team

Swan has always been at the forefront of technological progress, with four production and research and development sites strategically located in Montgomery, USA, Jinan, Xinjiang, and Inner Mongolia, China. These sites serve as Swann's strategic plants and laboratories in different regions, designed to meet diverse market needs and enhance technological innovation and product research and development capabilities. These production and research and development bases not only have advanced production equipment and laboratory facilities, but also have a highly skilled research and development team. Swan's research and development team consists of engineers, designers and scientists with extensive industry experience and expertise, dedicated to technological innovation and product development.

Through the layout of these production and research and development bases, Swan is able to better meet the needs of different regional markets, strengthen technological innovation and product research and development capabilities, and provide high-quality products and services.

Application

1. Cotton Processing: This machine helps to compress the raw cotton before further processing. It ensures that the cotton is packed tightly and reduces the size of the cotton, making it easier to handle during the production process.

2. Transportation: By compressing cotton fibers into bales, they become more compact and easier to transport. This reduces transportation costs because more bales can be loaded onto trucks, ships or trains.

3. Storage: Compressed bales take up less space and are easier to store. They can be efficiently stacked in warehouses or storage facilities, optimizing the use of available space.

Packing and Delivery

(1). Each machine is well supported and reinforced in the container to ensure safe access to the port of destination.

(2). The container loading and container seal will be recorded by photo or video, the whole process is visible and controllable.

(3). Cooperate with reliable shipping company, key time nodes are updated in real time.

Company Information

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd. is a listed company owned by Shandong Supply and Marketing Cooperatives. Its predecessor was founded in 1946. It collects scientific research & development, precision production ,marketing service and capital operation into a whole, and specially provides one-stop supply and service for mechanized ,intelligentized & informatized cotton processing equipments .Products have been exported to over 30 countries. The domestic market share ranks top for several years. The marketing service network spreads all over world main cotton production area.

Based on cotton machinery as main business, the company focuses on promoting the transformation and upgrading of cotton industry, creating a new era of smart factory, creating the first brand of cotton machinery in the world, actively expanding to the intelligent agricultural machinery equipment industry, and fully stepping into high-end equipment manufacturing industry.

Shandong Swan Cotton Industrial Machinery Stock Co., Ltd has four technical centers and manufacture bases in Jinan Shandong, Wujiaqu Xinjiang, Hailar Inner Mongolia and Montgomery USA , three national high-tech enterprises and six provincial innovation platforms , leading the technological progress of the industry for many years.It is a high-tech enterprise in Shandong Province, the technical support unit of "National Key Promotion Program of Scientific and Technological Achievements" and the undertaking unit of "13th five-year plan" National Key Research & Development Program.